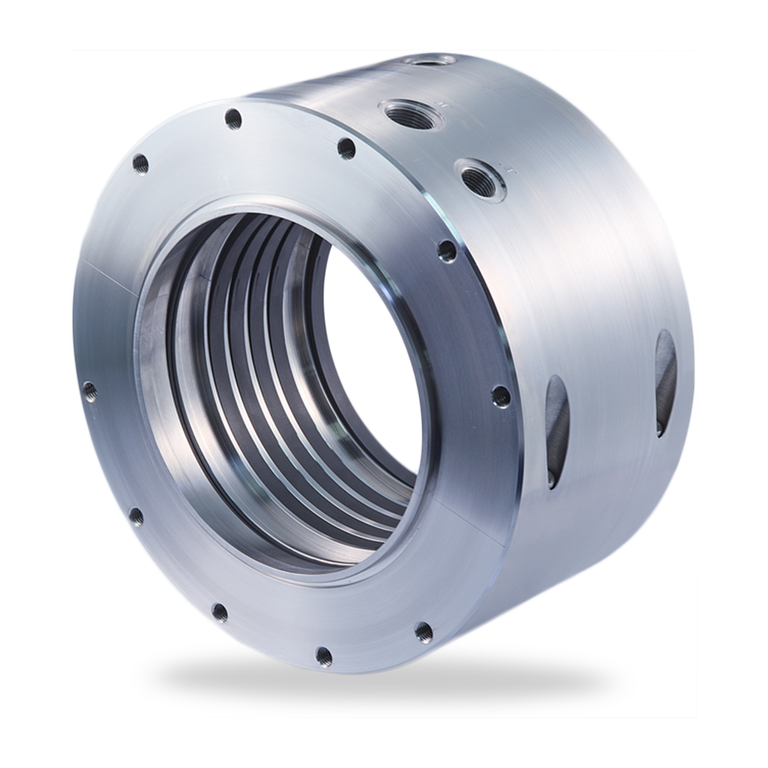

Espey WKA250ND

Espey WKA250ND

| Item | Description | Variable for width |

| 1.1 | Seal ring | |

| 1.2 | Tension spring | |

| 2 | Chamber | A |

| 2.1 | Chamber with O-Ring | A |

| 3 | Barrier gas chamber | B |

| 3.1 | Barrier gas chamber with O-Rings | B |

| 4 | Lantern chamber | C |

| 4.1 | Lantern chamber with O-Ring | C |

| 5 | Lantern thin | E |

| 5.1 | Lantern wide | F |

| 6 | End ring | G |

| 7 | Flat seal | H |

| 8* | Housing | |

| 9* | Lid | |

| 10* | O-Ring housing |

* On request

Espey WKA250ND

Features

- Chamber seal (modular design – can be combined in any order), optional with housing and lid

- Multi-part seal rings, radially cut

- Very small operation gap - low leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free - sliding faces and machine consume no additional power

- Balanced seal ring inside chamber

Advantages

- High reliability

- Long-term operation time

- Maintainability

- Segmented seal rings for easy replacement

Materials

Seal ring: Carbon, PTFE compound

Chamber and housing parts: 1.4021, 1.4571, Hastelloy®, Titanium, Inconel®, others

Tension spring: 1.4571, Hastelloy®, Titanium, Inconel®,

Secondardy seal (elastomer): Fluorocarbon rubber (Viton®), Nitrile-butadiene-rubber (Perbunan®), Perfluorocarbon rubber (Kalrez®)

Secondary seal (flat gasket): Statotherm®-HT/HD, KSiL C 4400

Chamber and housing parts: 1.4021, 1.4571, Hastelloy®, Titanium, Inconel®, others

Tension spring: 1.4571, Hastelloy®, Titanium, Inconel®,

Secondardy seal (elastomer): Fluorocarbon rubber (Viton®), Nitrile-butadiene-rubber (Perbunan®), Perfluorocarbon rubber (Kalrez®)

Secondary seal (flat gasket): Statotherm®-HT/HD, KSiL C 4400

Standards and approvals

- FDA

Recommended applications

- Oil and gas industry

- Refining technology

- Chemical industry

- Petrochemical industry

- Pulp and paper industry

- Metal production and processing

- Power plant technology

- CO2 transportation and storage

- Gases

- Fumes and exhaust, solids containing, flammable (Atex), acid containing and toxic gases

- (Solids containing) steams / liquid mist

- Oil mist / penetrating oil

- Water

- Integral-gear compressors (one or multi-stage)

- Screw and chiller compressors

- Steam turbines

- Air regulating devices

Similar products

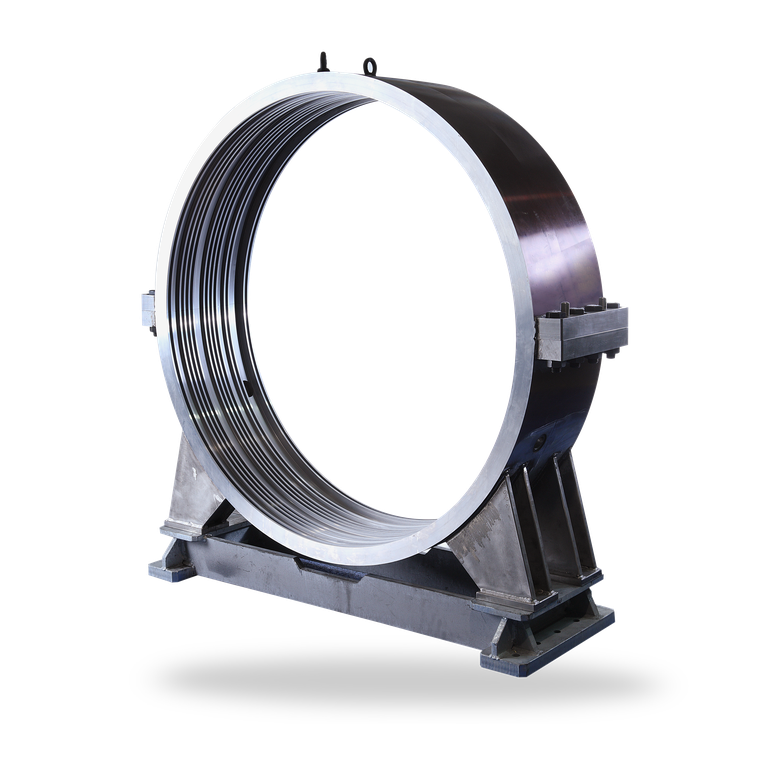

Espey Magna500+ the large seal for diameters from 500 mm

- Split housing design

- Segmented and self-adjusting seal rings

- Virtually maintenance- and wearfree

- Dry-running

- Suitable for horizontal and vertical use

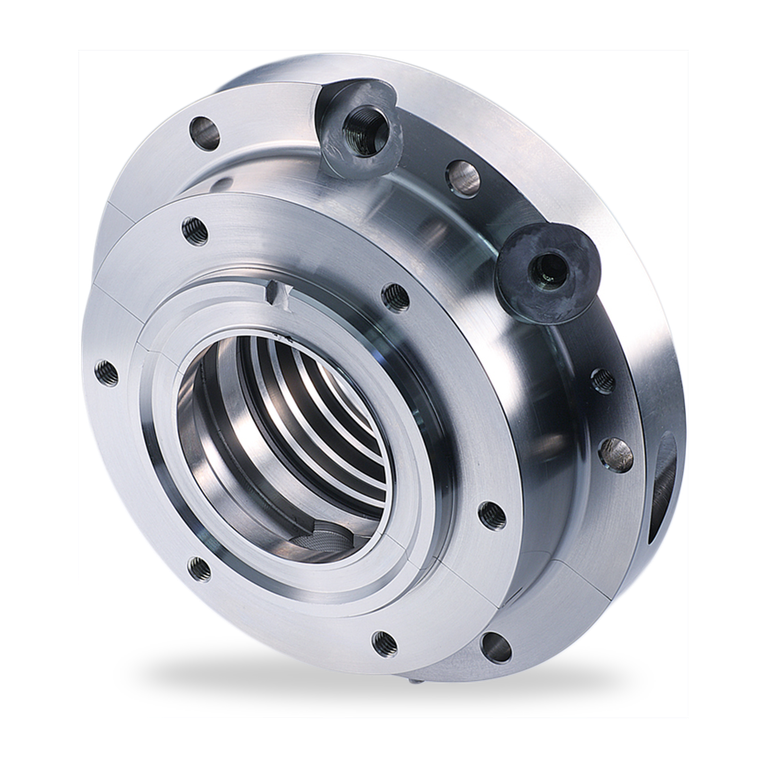

Espey WD200

- Split housing design

- Multi-part seal rings, radially cut

- Very small operation gap - low leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free - sliding faces and machine consume no additional power

Espey WD200/500

- Multi-part seal rings, radially cut on process side, overlapped mortised with gas tight joints on atmosphere side (adjusting)

- Split housing design

- Lowest possible operation gap - lowest leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- Short axial installation length

- No sealing components mounted on the shaft and hence no additional shaft vibrations