DF-SA DiamondFace

DF-SA DiamondFace

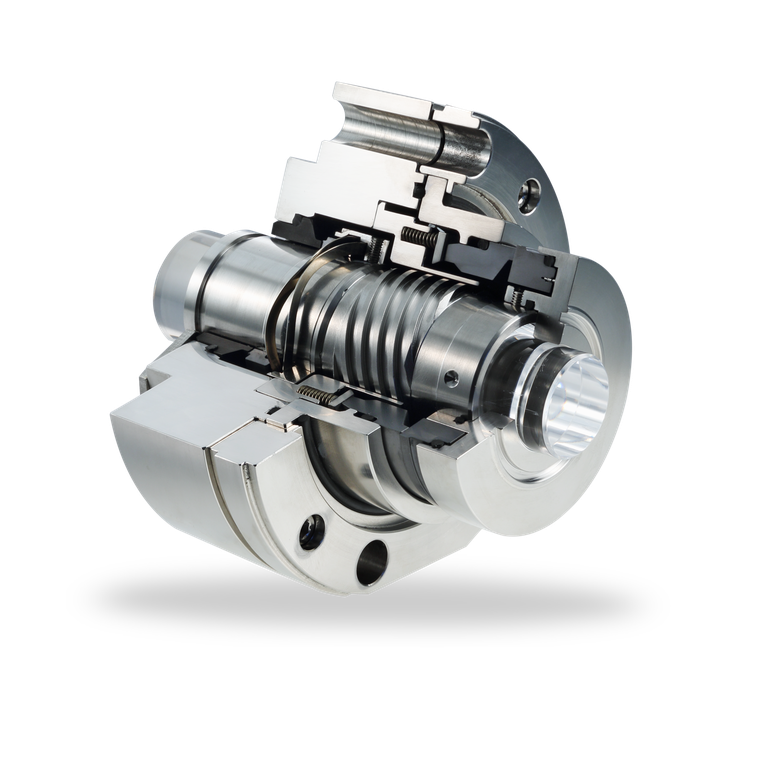

| Item | Description |

| 1 | Seal ring |

| 2 | O-Ring |

| 3 | Spring |

| 4 | O-Ring |

| 5 | Seat collar |

| 6 | Mating ring (DiamondFace coated) |

| 7 | Shaft sleeve |

| 8 | Pumping sleeve |

| 9 | Cover |

DF-SA DiamondFace

Features

- Cartridge design

- Single seal

- Balanced

- Integrated pumping device

- Stationary spring loaded unit

- Inserted seal ring

- Rotating mating ring

(DiamondFace coated)

Advantages

- Resistant to electrochemical corrosion.

- Extremely long service life (>40,000 h).

- No dosing system, no cooling circuit conditioning required.

- Diamond coating provides very low friction, thus reduced power consumption.

- Deformation-optimized for high sliding velocities and medium pressures.

- Economical due to standardized components.

- High flexibility due to adaptation of the connection parts to the pump seal chamber.

- Optimum heat dissipation due to integrated pumping device and optimized seat / seal face design.

Materials

Seal face: Composite carbon

Seat: SiC DiamondFace coated

Secondary seals: EPDM (E), FFKM (K)

Springs: CrNiMo steel (G)

Metal parts: CrNiMo steel (G)

Seat: SiC DiamondFace coated

Secondary seals: EPDM (E), FFKM (K)

Springs: CrNiMo steel (G)

Metal parts: CrNiMo steel (G)

Recommended applications

- Power plant technology

- Power generation

- Boiler feed pumps

Recommended piping plans

API Plan 02 + 23 (with jacket cooling)

Similar products

DF-(P)DGS6

- Dry gas seal for multiphase pump applications

- DiamondFace sliding surface technology

- Ideal for applications with Ethane, CO2, and similar media with low vapor margins

- Shrouded rotating ring

- Bi-directional

- Ready-to-fit cartridge unit

- Single, double, tandem, and tandem with intermediate labyrinth available

HR

- Single seal

- Balanced

- Independent of direction of rotation

- Multiple springs stationary

- Seat rotating

- Seat arranged directly behind the impeller

- Spring protection sleeve

- Variant with cylindrical spring and acc. EN 12756 (HRZ1) available

- Variant as cartridge with/without guide sleeve for application with/without quench (HR2, HR3)

- Dual seal as cartridge unit (HRKS-D) available

HRC...N

- Cartridge

- Balanced

- Independent of direction of rotation

- Stationary multiple springs

- Spring protection sleeve

- Variant for operation with pressureless quench available (HRC2000N)

- Dual seal with and without pumping screw (HRC3300NF, HRC3300N) available